Økende krav til renhetsanalyser av plast

Produkter som inneholder mekanisk resirkulert plast har mange utfordringer som begrenser bruken. Resirkulert plast i kontaktsensitive applikasjoner som kosmetikk, leker og materialer i kontakt med mat må gjøres trygt for forbrukerne. På grunn av den potensielle risikoen for kontaminering, kreves avansert karakterisering og testing. Vår partner Norner er involvert i ulike forskningsprosjekter knyttet til additiv-og forurensningskarakterisering av resirkulert plast.

Increasing requirements on purity analyses of plastic

Av Yvonne Hed, Charlotte Waag, Bavan Mylvagnam, Steffen Annfinsen og Ida Marie Wold - Norner

EU is introducing requirements to converters within packaging, building and construction, automotive, and several other applications where plastics are being used. The proposed Plastic and Packaging Waste Regulative (PPWR) states that by 2030, the minimum amount of recycled content of single-use plastic beverage bottles will be 30 %, and the number will increase to 65% by 2040. Similar targets will be published for other applications, and these are tough requirements to meet for the industry. The race to build knowledge and competence within plastic recycling and characterization of the resulting products is at full speed.

Challenges with recycled plastics Products containing mechanically recycled plastics have many challenges that limit their usage, especially in high-value applications such as food, cosmetic products, UN packaging, and plastic toys. Poor mechanical properties, unwanted odours, polymer degradation, colour inconsistency, and organic and inorganic contaminations are some of the challenges that need to be addressed.

Advanced characterization

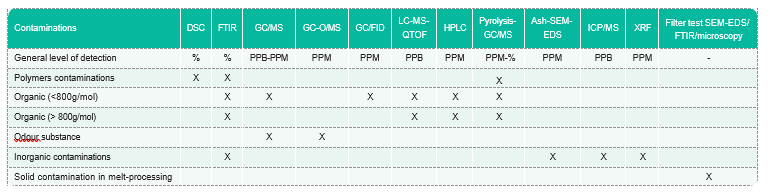

The introduction of recycled plastics in contact-sensitive applications such as cosmetics, toys, and food contact materials needs to be made safe for consumers. Due to potential risks of contamination, advanced characterisation and testing are required. A normal procedure so far has involved migration tests according to the food packaging regulation EU 10/2011 followed by GC-MS screening and specific target analysis. However, alternative techniques to detect more substances at even lower concentrations will be needed. To meet these increasing demands, Norner has invested in state-of-the-art equipment and is developing methods for the separation, identification, and quantification of known and unknown organic compounds. The new techniques are based on Pyrolysis (PY) GCMS and Liquid Chromatography (LC) coupled with high-resolution mass spectrometry through a Quadrupole Time of Flight (Q-TOF) detection system. The new equipment and methods are complementary to Norner’s other capabilities within purity analysis like migration and GC/MS, and we can now offer a comprehensive set of services as visualized in Figure 1.

Figure 1 Typical method selections for different classes of contaminations

Collaboration with academia

Norner is involved in various research projects related to additive and contaminant characterization with recycled plastics. In 2019, Norner initiated a collaboration with the Royal Institute of Technology in Stockholm, KTH, where the focus is to increase the knowledge around the purity of Post Consumer Recyclates (PCRS). The current research focus in this col- laboration is studies of post-consumer recycled plastics in food contact.

Norner's research efforts

We have developments ongoing in various fields such as food, pharmaceuticals, automotive, and infrastructure:

- Identification of unknown peaks, large and small molecules (MW range up to 10,000 Da). The LC/Q-TOF has a mass accuracy that is 100 times better than con- ventional methods such as HPLC/ MS. PY-GCMS does not have an upper MW limitation, and a very small sample amount can give a lot of relevant information.

- Extractables and Leachables (E&L) testing – detection of compounds at very low levels (ppb), with the use of an extensive library available at Norner

-

Verification of 10 ppb fppd regulative requirement (ECHA)

-

Target analysis with low detection levels for polyaromatic hydro- carbons (PAH) and polyaromatic amines (PAA)

-

Improved identification and quantification of large molecules (> 700-800 Da) by combining FTIR, LC/Q-TOF, and PY-GCMS.

Pyrolysis-GCMS

Pyrolysis-GCMS is a powerful technique used to identify and characterize polymers. It involves the controlled heating of polymer samples to break them down into small components (pyrolysates), which are then separated and analysed using Gas Chromatography and Mass Spectrometry. This technique provides valuable information about the polymer’s chemical structure, thermal stability, degradation products, and more.

LC/Q-TOF

LC/Q-TOF is a powerful analytical technique used for the separation, identification, and quantification of non-volatile components. It offers high resolution, sensitivity, and mass accuracy for reliable and precise analysis. It combines the capabilities of ultra-high liquid chromatography, which separates the non-volatile components with high-resolution mass spectrometry for accurate identification and characterization of the separated components